![]() Customer Support +91 2135 628400 / 01 / 02 / 03

Customer Support +91 2135 628400 / 01 / 02 / 03

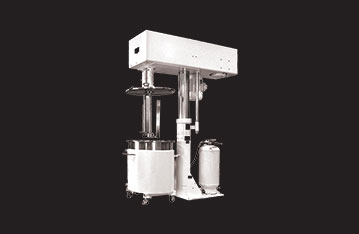

Thousands of

Ross Mixers.

Millions of Batteries.

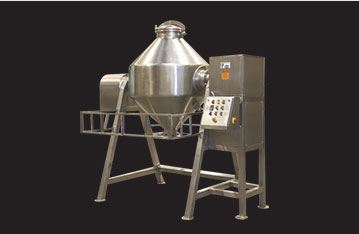

Mixing, Blending, Drying & Dispersion equipment

for the battery industry

Rapid mixing for

tablet coating

SLIM Technology and Ultra-High Shear Mixers

Blend it like

Ross’ Blenders

Clean design, meticulous finish and faster blending

cycles for the food industry

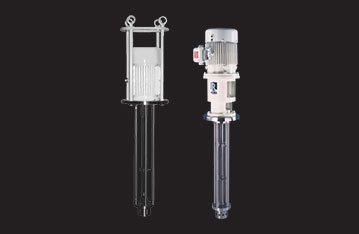

Adhesives and Sealants

Adhesives and Sealants